NCC 2022 Volume One - Building Code of Australia Class 2 to 9 buildings

Search the National Construction Code editions

F3

Part F3 Roof and wall claddingThis Part is intended to minimise the risk of water, including surface water and rainwater, entering the building and causing musty, damp and unhealthy conditions or damaging building elements by corrosion or other degradation. It is also intended to prevent water redirected away from the outside of the building damaging nearby properties.

The Objective of this Part is to—

F3O1 aims to minimise the risk of occupant illness or injury, and protect buildings from being damaged, by ingress of water from outside the building and the accumulation of moisture within the building.

A building is to be constructed to prevent penetration of water from the outside.

The construction of a building must prevent water from outside entering the building.

A roof and external wall (including openings around windows and doors) must prevent the penetration of water that could cause—

F3P1 does not apply to—

Roofs and external walls (including windows, doors and other openings within the external walls) must prevent water penetration which could cause dangerous conditions, loss of amenity or dampness and deterioration of building elements

The limitations contain several exemptions to F3P1. These are based on the belief that the use and safety levels of the exempted buildings will not be significantly diminished by water entering them.

Limitation (a), regarding Class 7 and Class 8 buildings, refers only to such buildings which, in a particular case, do not exhibit any need for compliance with F3P1. Such buildings must be considered on a case-by-case basis. However, it is the responsibility of a building proponent to satisfy the appropriate authority that the exemption should apply.

| Risk factor | Category | Risk severity | Score |

|---|---|---|---|

| Wind region | Region A0-5 (AS/NZS 1170.2) | Low to medium | 0 |

| Region B1-2 (AS/NZS 1170.2) | |||

| Region C (AS/NZS 1170.2) | High | 1 | |

| Region D (AS/NZS 1170.2) | Very high | 2 | |

| Number of storeys | One storey | Low | 0 |

| Two storeys in part | Medium | 1 | |

| Two storeys | High | 2 | |

| More than two storeys | Very high | 4 | |

| Roof/wall junctions | Roof-to-wall junctions fully protected | Low | 0 |

| Roof-to-wall junctions partially exposed | Medium | 1 | |

| Roof-to-wall junctions fully exposed | High | 3 | |

| Roof elements finishing within the boundaries formed by the external walls | Very high | 5 | |

| Eaves width | More than 600 mm for single storey | Low | 0 |

| 451-600 mm for single storey | Medium | 1 | |

| More than 600 mm for two storey | |||

| 101-450 mm for single storey | High | 2 | |

| 451-600 mm for two storey | |||

| More than 600 mm for above two storey | |||

| 0-100 mm for single storey | Very high | 5 | |

| 0-450 mm for two storey | |||

| Less than 600 mm for above two storey | |||

| Envelope complexity | Simple shape with single cladding type | Low | 0 |

| Complex shape with not more than two cladding types | Medium | 1 | |

| Complex shape with more than two cladding types | High | 3 | |

| As for high risk but with fully exposed roof-to-wall junctions | Very high | 6 | |

| Decks, porches and balconies | None | Low | 0 |

| Timber slat deck or porch at ground level | |||

| Fully covered in plan view by roof | Medium | 2 | |

| Timber slat deck attached at first or second floor level | |||

| Balcony exposed in plan view at first floor level | High | 4 | |

| Balcony cantilevered at first floor level | |||

| Balcony exposed in plan view at second floor level or above | Very high | 6 | |

| Balcony cantilevered at second floor level or above |

| Stage number | Serviceability wind pressure (%) | |

|---|---|---|

| Min | Max | |

| 1 | 15 | 30 |

| 2 | 20 | 40 |

| 3 | 30 | 60 |

F3V1 is a means to verify whether or not a proposed external wall achieves the requirements of F3P1, i.e. whether the wall prevents the penetration of water that could cause:

F3V1 is not a mandatory component of the NCC; however, it is one form of assessment method that can be used to demonstrate compliance with the Performance Requirements.

Other assessment methods in the NCC include:

The Verification Method must be applied in the following order:

This process is shown in Figure F3V1a.

Figure F3V1a: Process for applying F3V1

The risk score is determined by a number of factors including:

The following are examples of typical roof/wall junctions and their associated exposureor protection categories:

Building envelope complexity is determined by the shape and the amount of cladding used. F3V1 includes both simple and complex shaped buildings:

Test specimen—F3V1(3)

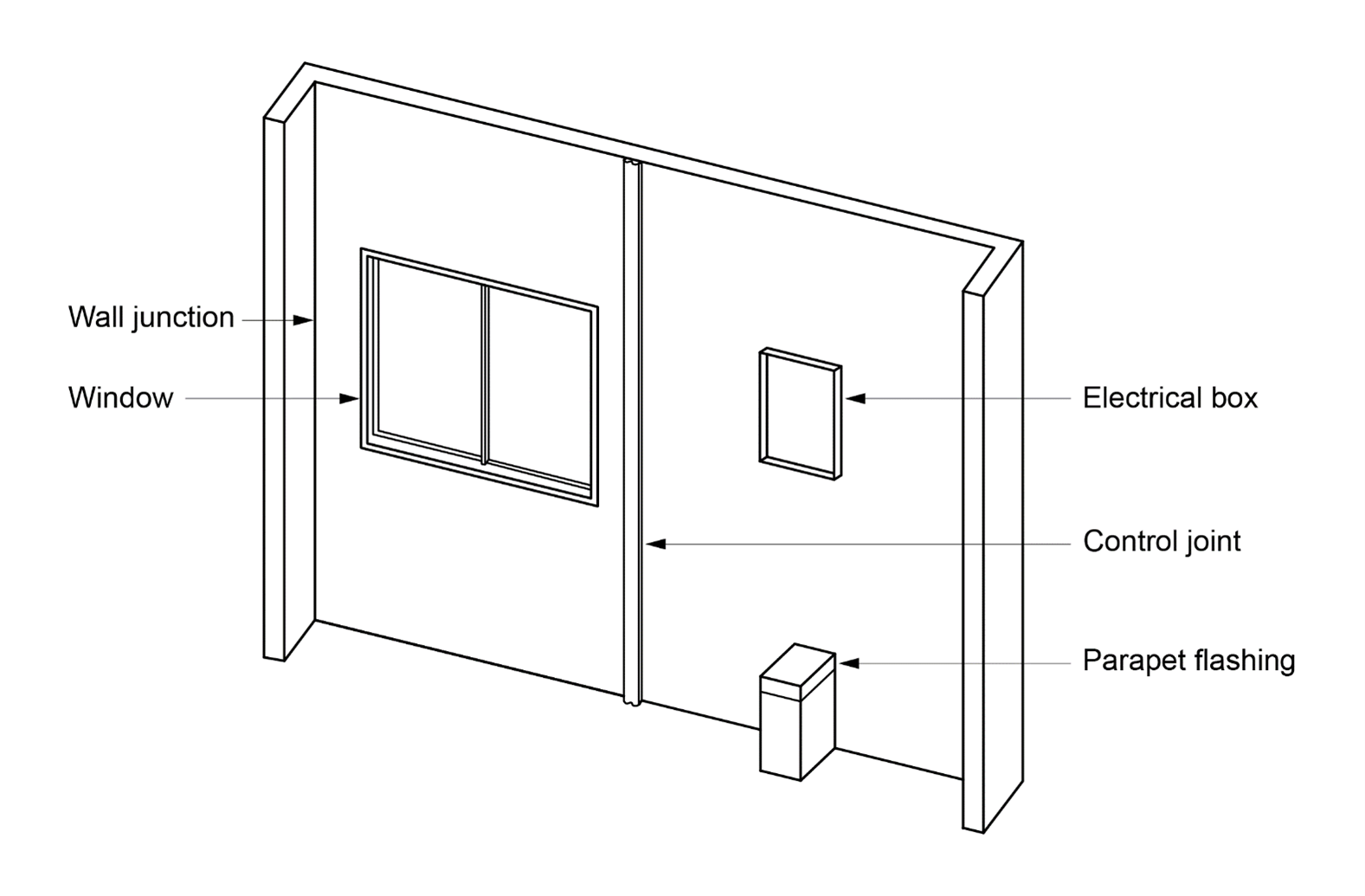

Representative samples of openings and joints must be includedto test the whole cladding system. This includes samples of:

A test specimenis illustrated in Figure F3V1b

Figure F3V1b: Illustration of a test specimen

Where a cavity wall is tested, a transparent material must be used in lieu of a portion of the internal wall lining. The transparent material will be used during the testing to observe any water penetration. To ensure an unobstructed view of the external wall occurs, other building components such as building membranes must be removed for the extent of the transparent opening within the internal wall lining. It should be noted that for the purposes of F3P1 building membranes are not a requirement. However, a membrane can be used to achieve compliance with F3V1.

The transparent material must be installed to maintain similar air tightness as the intended internal wall lining. To simulate the effects of power points, light switches and other similar openings which may cause air leakage, a 15 mm diameter hole must be placed in the internal wall lining below the window.

The test procedure requirements vary in relation to two sub-clauses. F3V1(4) specifies the test procedure for a direct fix cladding wall or a unique wall. F3V1(5) specifies the requirements for cavity wall construction. The difference betweenthe two sub-clauses is F3V1(5) has an additional water management test. This is due to cavity wall construction being designed to allow water to pass through the primary weather-defence (e.g. the skin of masonry on a masonry veneer wall), with the function of the cavity allowing for the removal of any water.

The test procedure for F3V1(4) contains three steps:

Apply cyclic pressure and test the water penetration in accordance with clause 8.6.2of AS/NZS 4284, tested over the three stages specified in Table F3V1b.

The test procedure for F3V1(5) contains four steps:

F3V1(5)(d) contains the additional testing requirements for a cavity wall. This test represents the failure of the primary weather defence or sealing. The primary weather defence includes the wall material, any flashings and sealing of joints and openings.

Similar to the test procedure, the compliance requirements are separated into two parts and are subject to the type of wall being tested.

F3V1(6)(a) specifies the compliance requirements for a direct fix cladding wall and a unique wall. Compliance for the testing of these types of walls is met by no presence of water to the inside surface of the facade. This includes the surface of the external wall which is fixed to the internal wall, or for a single skin wall, the internal wall.

The compliance requirements for a cavity wall in F3V1(6)(b) are different to the requirements for a direct fix cladding wall or unique wall. This is due to the purpose and nature of a cavity wall. Water which passes through the primary weather- defence will gradually be removed from the cavity either through weep holes or evaporation. F3V1(6)(b) therefore allows water to enter the cavity provided water is not present on the removed surface of the cavity. However, there are some exemptions to this, as the water may transfer to the removed surface through an isolated blemish due to the introduced defects. Also, water can contact cavity surfaces such as battens. However, it must be demonstrated that the water will be able to be removed from these surfaces.

The removed surface of the cavity will generally be the outer surface of the internal wall, for example,where the building membrane would be attached to a stud frame.

The purpose of the test report in F3V1(7) is to record the details and the outcomes of the test. This is common for any test procedure.

To clarify that the requirements of F3P1 will be satisfied if compliance is achieved with F3D2 to F3D5.

A roof must be covered with—

To prevent water penetration of roofs which could cause unhealthy and dangerous conditions or loss of amenity for occupants or dampness and deterioration of building elements.

F3D2 contains reference to Australian Standards and other reference documents for a range of roofing materials and fixing methods suitable for the prevention of water penetration.

Sarking-type material used for weatherproofing of roofs and walls must comply with AS 4200.1 and AS 4200.2.

To prevent water penetration of roofs and walls which could cause unhealthy and dangerous conditions or loss of amenity for occupants or dampness and deterioration of building elements.

F3D3 references the Standard for sarking materials where sarking is required for weatherproofing roofs and walls (e.g. under roof tiles or on walls before weatherboards are fixed).

To prevent water penetration via glazed assemblies of an external wall which could cause unhealthy and dangerous conditions or loss of amenity for occupants or dampness and deterioration of building elements.

F3D4 requires glazing in an external wall to complywith the AS 2047 requirements for resistance to water penetration. The provision does not apply to:

F3D4(3) provides a list of glazing assemblies which do not need to comply with F3D4. AS 2047 does not cover these types of windows and therefore has been exempted as per the standard.

To prevent water penetration via external walls which could cause unhealthy and dangerous conditions or loss of amenity for occupants or dampness and deterioration of building elements.

F3D5 provides Deemed-to-Satisfy Provisions for the weatherproofing external wall cladding, offering specific methods based on the material used. If masonry is selected, including masonry veneer, unreinforced, and reinforced masonry, compliance with AS 3700 achieves weatherproofing requirements. Autoclaved aerated concrete is to adhere to AS 5146.3, while metal wall cladding needs to meet AS 1562.1.

If compliance with F3D5 is not met, a Performance Solution may be used to achieve compliance with the Performance Requirement.

F3D5(2) provides exemptions for certain building types. Class 7 or 8 buildings are exempt unless there's a specific need for compliance. Garages, tool sheds, and sanitary compartments are also exempt, provided they do not contribute to the weatherproofing of another part of a building that needs to be weatherproofed. Lastly, open spectator stands and open deck carparks are not required to comply with these provisions.